Molding and casting

Casting can be used to make multiple parts quickly.

Material Safety Data Sheet

Silicone

This is the material safety data sheet for the silicone used for molding.

These are the properties of the silicone. It's important to takenote of the pot life(working time) and cure time.

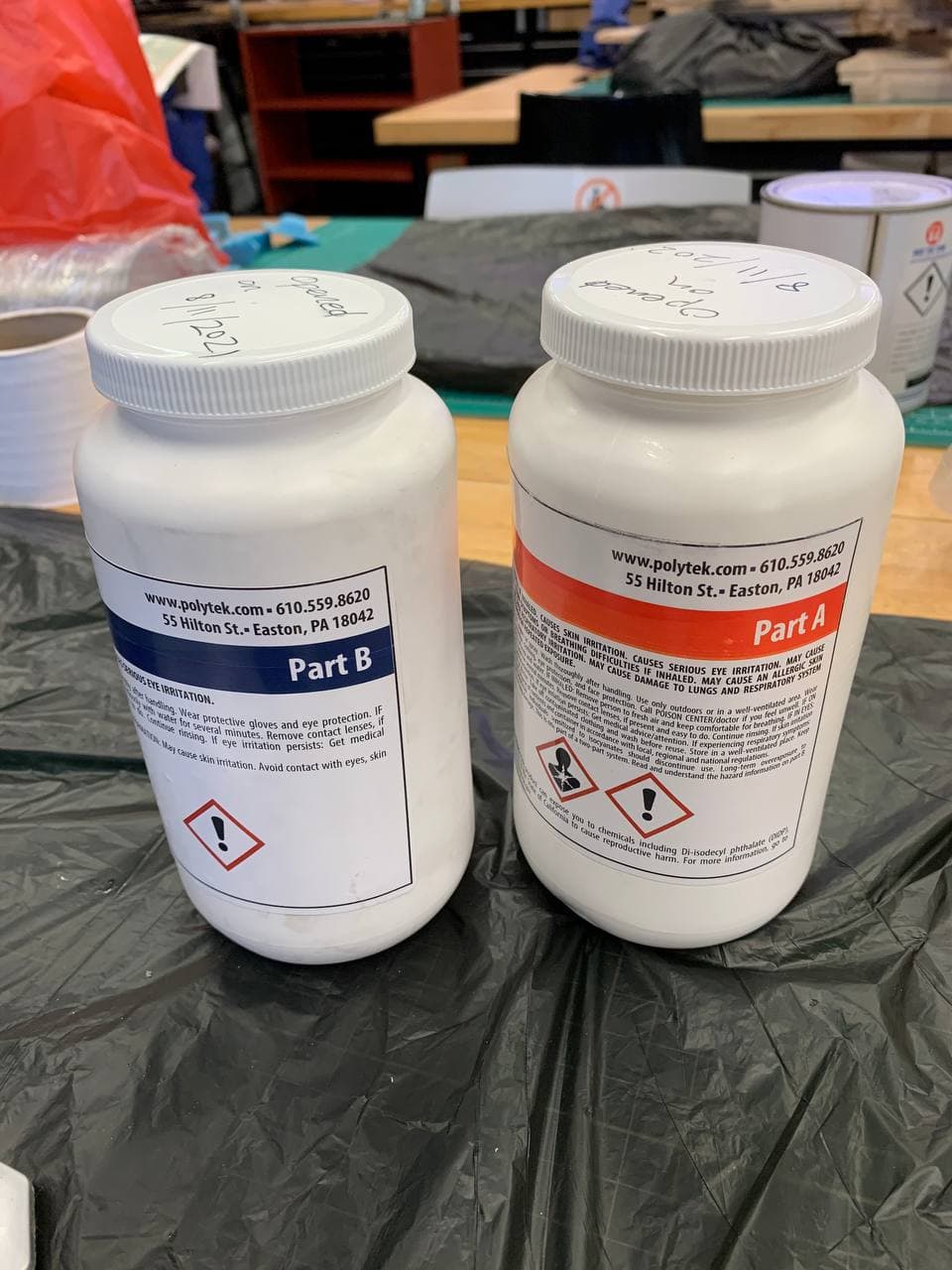

Epoxy resin

These are the resins used for casting.

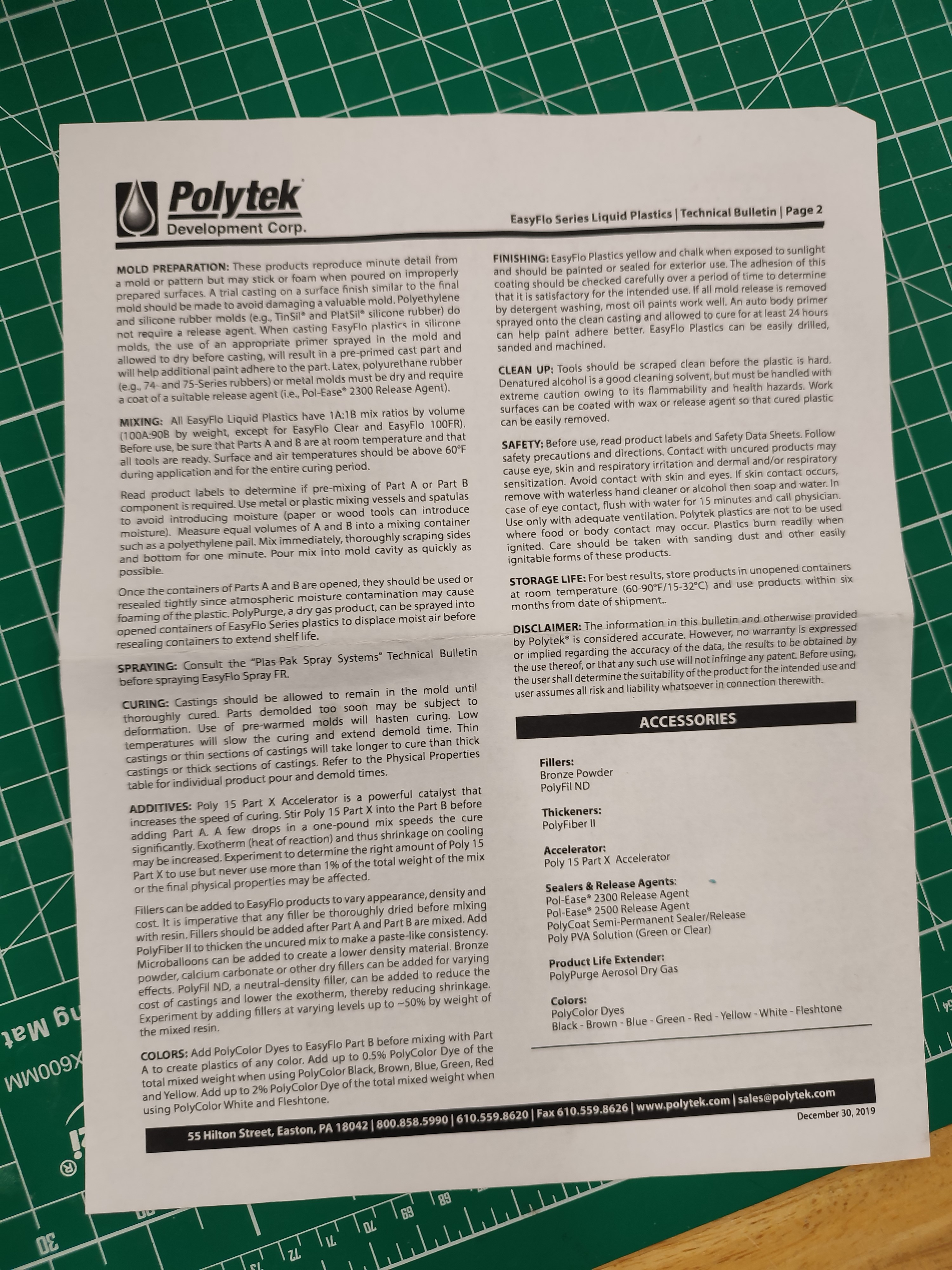

This is the material datasheet.

These are the specifications of the various epoxy resins.

The mixing instructions are here.

The cureing process is here.

Here, safety precautions for handling the epoxy resin can be found.

Silicone pour

This is the silicone used for molding.

The silicone is mixed 1:1 by weight. A weingh scale is used to measure the weight.

The first part is poured.

The second part is poured.

The silicone is poured into the corner so that htere would not be any trapped air bubbles on the surface of the model.

The mold is filled up to the top.

The silicone pour is done.

The silicone mold has set after 24 hours.

The foam is broken off.

The silicone mold is peeled away from the foam.

This is the completed silicone mold.

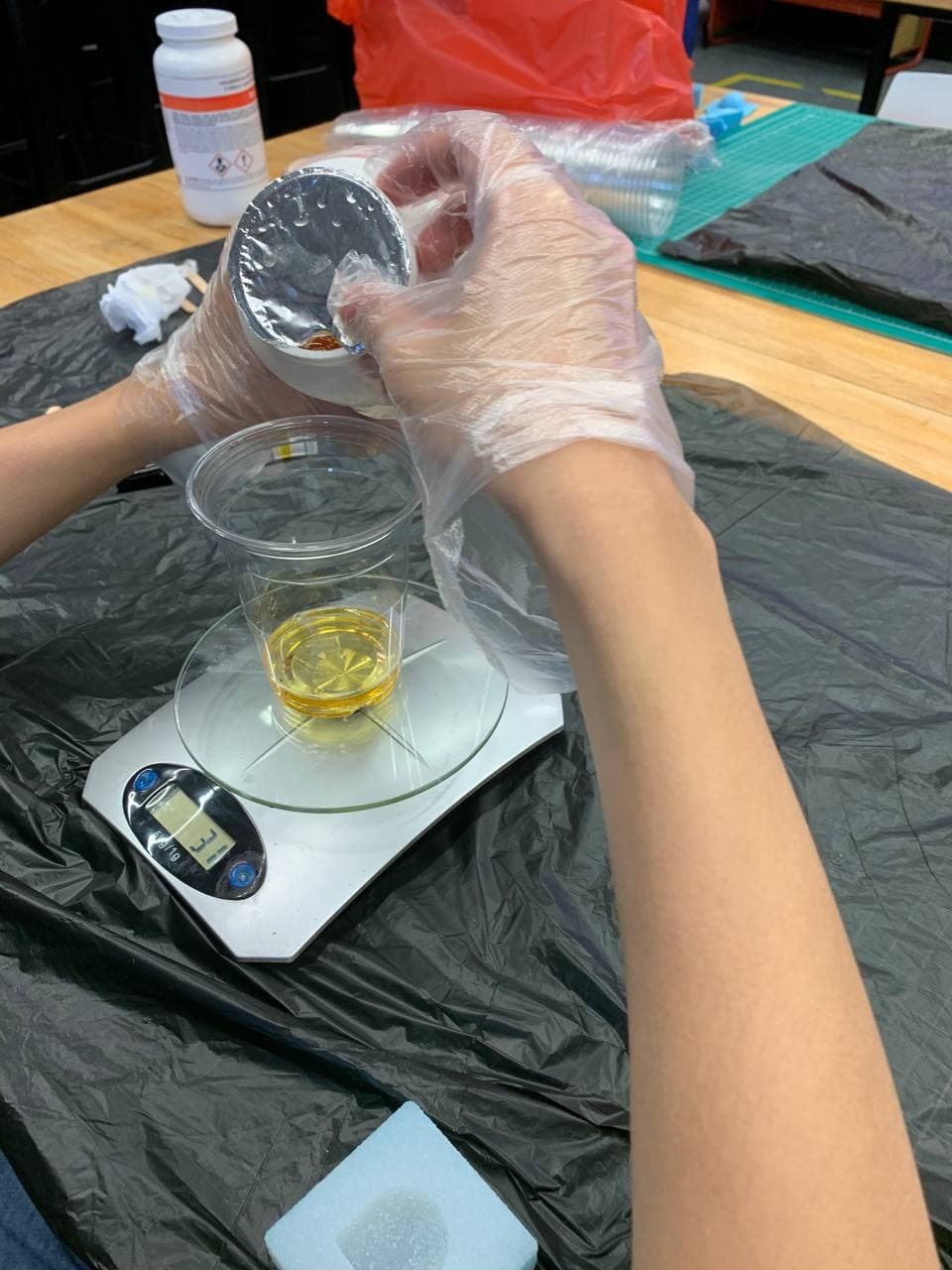

Epoxy casting

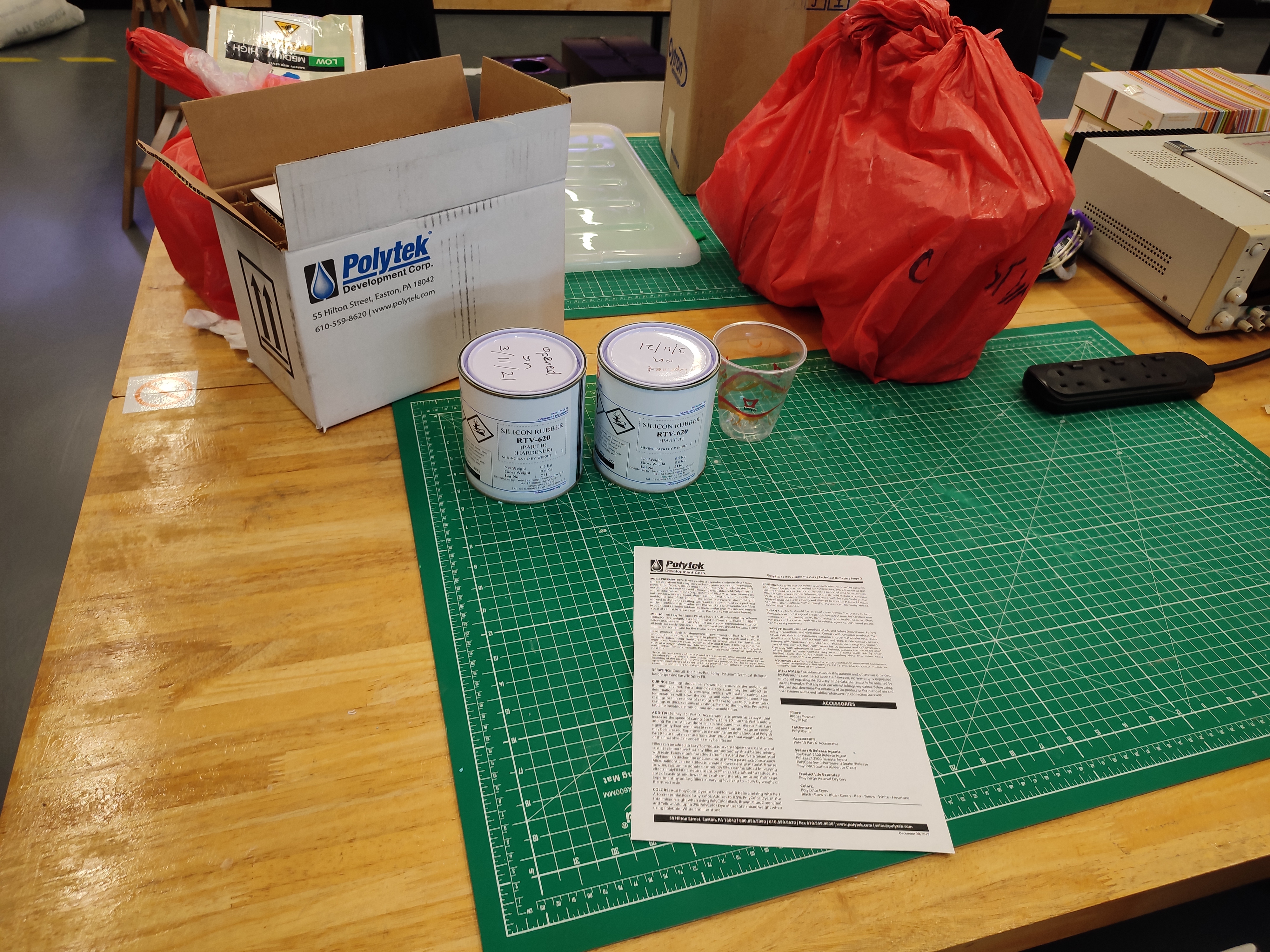

This is the resin used for casting.

The first part is poured.

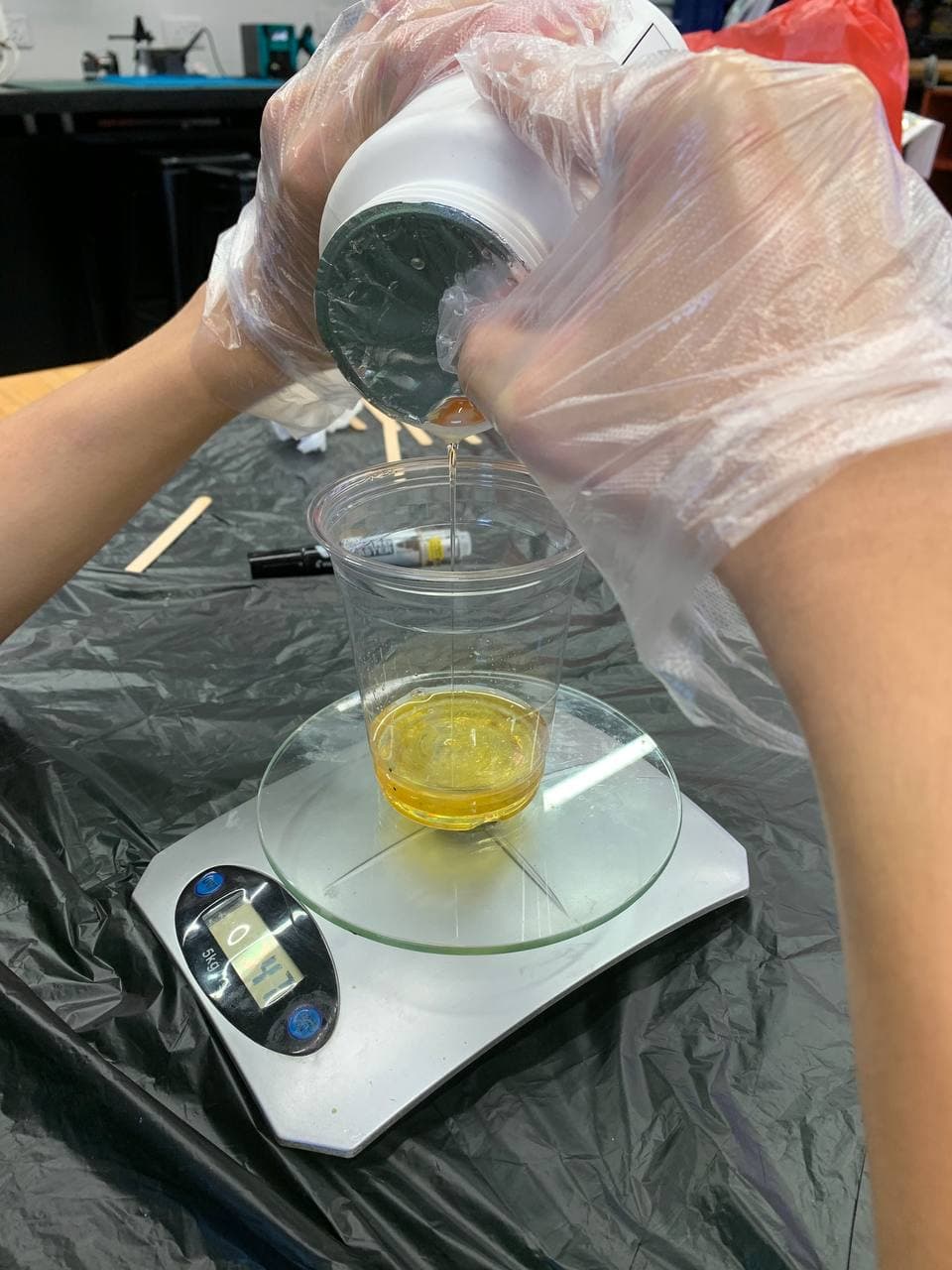

The second part is poured.

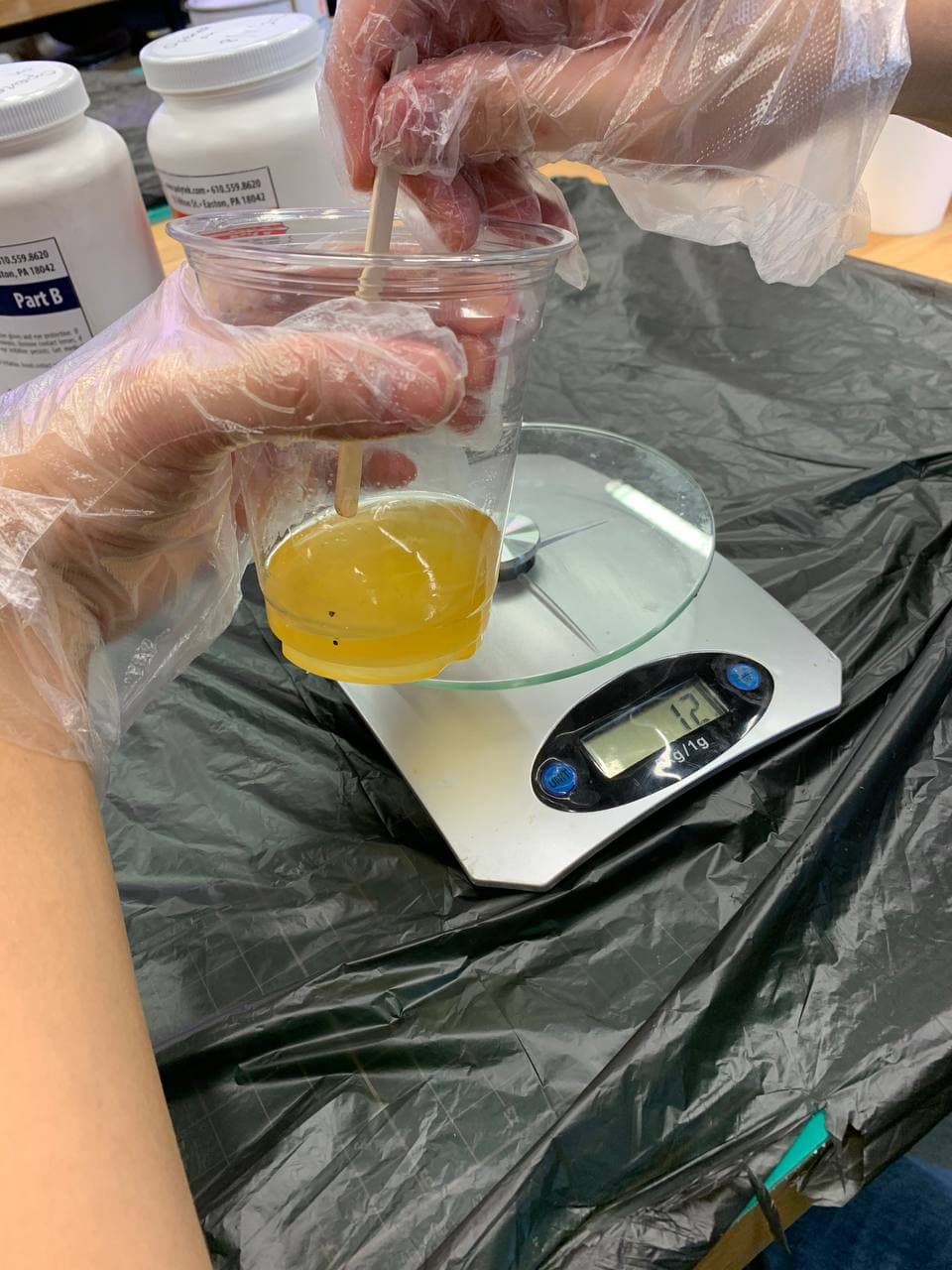

The resin is mixed.

The mold is filled.

The mold has been filled.

The resin is setting. It slowly becomes opaque.

The resin has set.

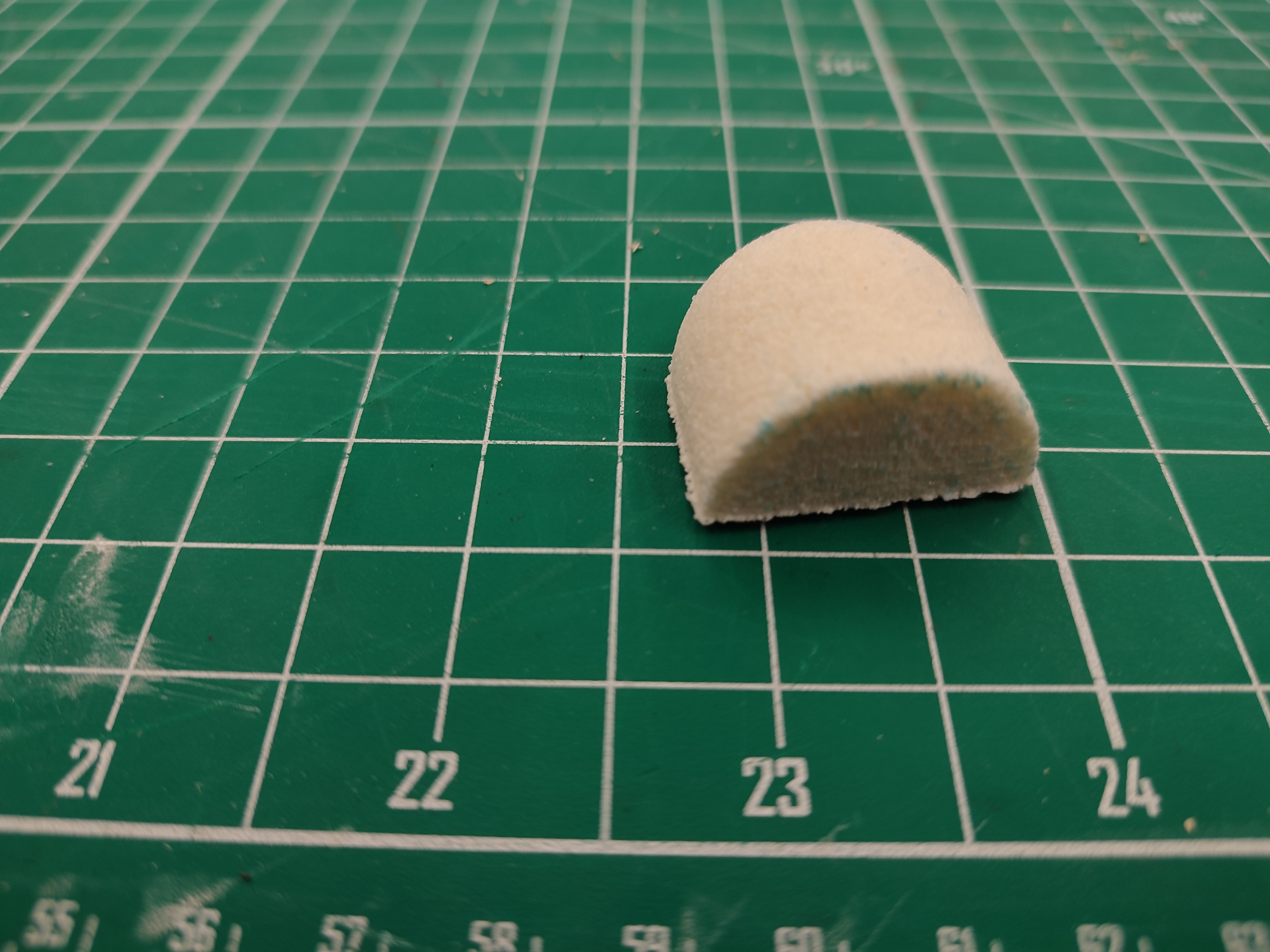

The part can be demolded.

The silicone is peeled away.

And the part is pushed out.

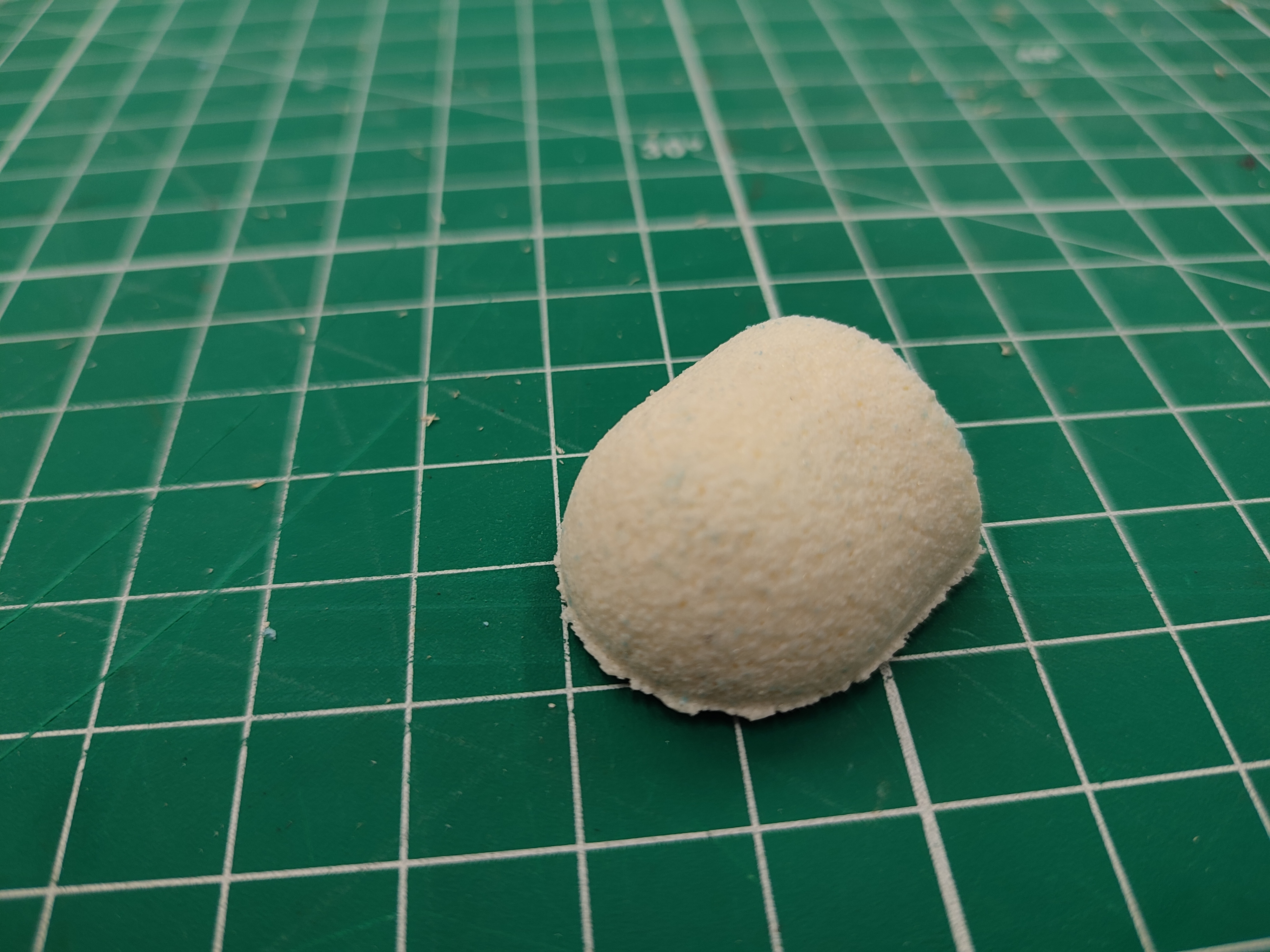

This is the completed part.