Laser cutting

Laser cutting is a process where a high powered laser is used to melt or vaporise the material to be cut.

Click on a link below to jump to a section:

Music box CAD

The mechanism is measured and created in CAD.

The variables for the music box are created.

The sketch of the base is drawn.

The base is extruded.

The front panel is sketched.

The front is extruded.

The back is created by transforming and copying the front.

The main sketch for the side is created.

The side is extruded.

The hinge is sketched for the side panel as well as the top panel.

The hinge is extruded.

The excess material from the main side panel is removed.

The other side is created by transforming and copying the front.

A sketch for a hole for the crank is created.

The hole is extruded.

The hinge of the top panel is extruded.

The main top panel is sketched.

The top panel is extruded.

A tab is sketched so the music box can be easilly opened.

The tab is extruded.

A drawing is created of the music box and exported as a DXF file.

Click image to download CAD files:

Music box Laser cutting

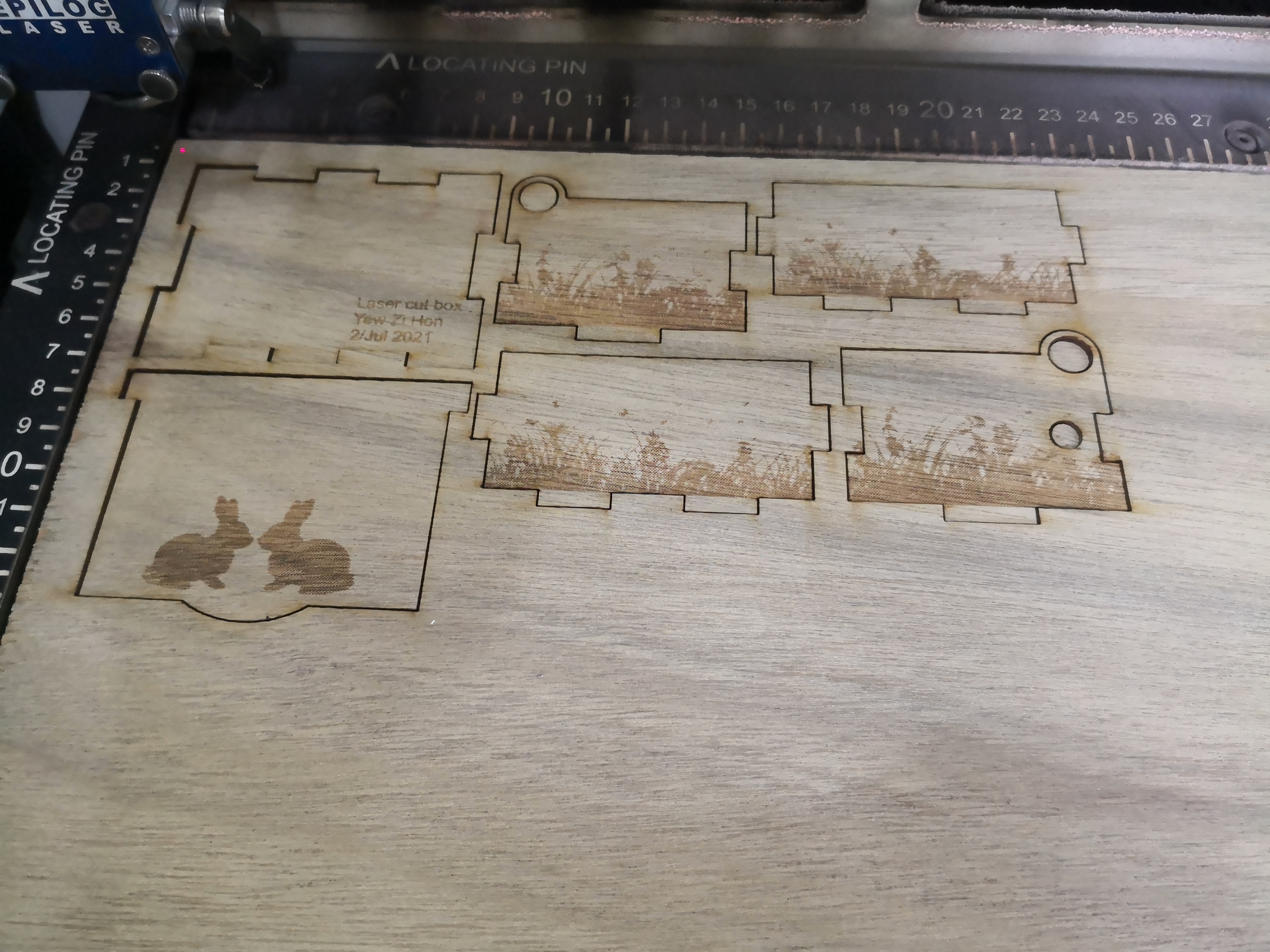

The DXF file and raster images is imported into CorelDraw and positioned properly

The music box is sent to the laser cutter to be cut.

Raster engraving.

Laser cutter vector engraving.

Laser cutting done.

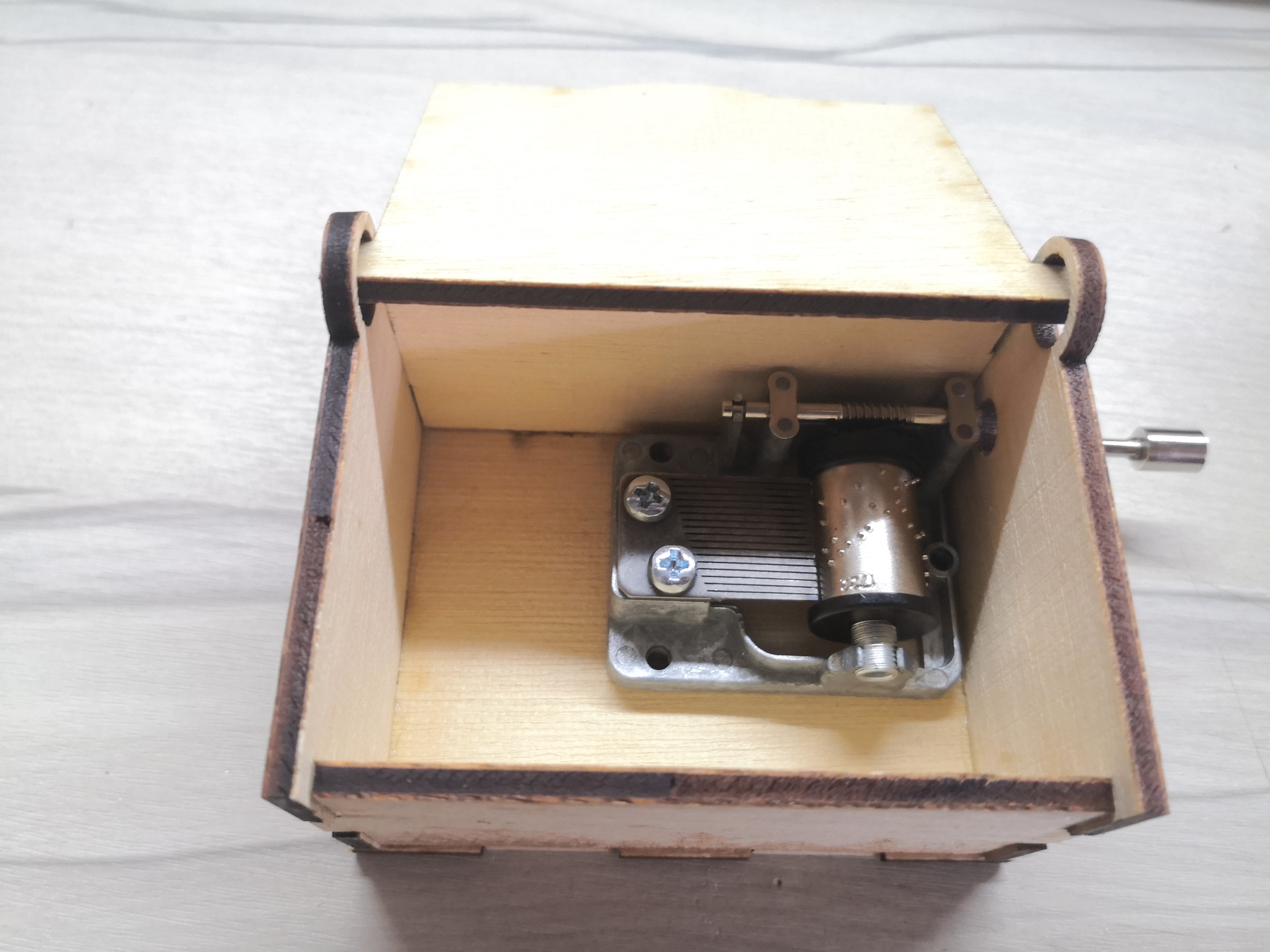

Music box assembly

The parts are cut from plywood.

The back side panel is glued on.

The right side is glued on.

The top panel is put in place. then, the left panel is glued on.

The front panel is glued on last.

The music box is done.

The mechanism is placed in the music box.